Monthly Archives: March 2023

-

Posted: March 31, 2023Categories: Elkwall Wood Art Printing And DesignRead more »

Tung oil and beeswax are often used in woodworking to create a natural and authentic finish that emphasizes the natural beauty of the wood when creating signs and pictures. Here is a general guide on how to use them to create an aged or antique appearance:

Sand the Wood: First, sand the wood surface to create a smooth and even surface. Make sure to remove all the dust and debris.

Apply Tung Oil: Use a cloth or brush to apply tung oil to the wood surface. Tung oil is a natural oil that penetrates the wood grain to create a protective layer. Allow it to dry for at least 24 hours.

Sand Again: After the tung oil has dried, use a fine-grit sandpaper to lightly sand the surface. This will help to remove any raised grain or rough spots.

Apply Beeswax: Using a cloth or brush, apply a thin layer of melted beeswax to the surface. Beeswax is a natural wax that provides a protective coating and a soft sheen to the wood surface. Work in small areas at a time -

Posted: March 30, 2023Categories: Elkwall Wood Art Printing And DesignRead more »

Wood tavern signs have a long history, dating back to the Middle Ages in Europe when businesses began to use signs to indicate their presence to passersby. Taverns and inns, in particular, used signs to attract travelers and customers who could not read, as many people were illiterate at the time.

The earliest tavern signs were often simple wooden boards with painted or carved images, such as a mug of beer or a bed to indicate a place to stay. Over time, tavern signs became more elaborate and ornate, with designs featuring animals, people, and landscapes.

In colonial America, tavern signs were a common sight and often featured patriotic symbols such as eagles and flags. They were also used to identify specific taverns and inns, which were important gathering places for socializing, conducting business, and political discussion.

Today, wood tavern signs continue to be popular for their nostalgic and rustic charm, as well as their durability and weather-resistance.

-

Posted: March 30, 2023Categories: Elkwall Wood Art Printing And DesignRead more »

There are several ways to apply stain to wood for pictures and other wood wall decor, but the following steps should help you achieve a smooth and even finish:

Sand the wood: Begin by sanding the wood with fine-grit sandpaper to create a smooth surface. Sanding also helps to open up the wood's pores, allowing the stain to penetrate evenly.

Clean the wood: Use a clean, dry cloth to remove any dust and debris from the wood.

Apply the stain: Stir the stain thoroughly before applying it with a brush or cloth, following the manufacturer's instructions. Work in small sections and apply the stain evenly in the direction of the wood grain. Wipe off any excess stain with a clean cloth, working quickly to avoid blotches and streaks.

Allow the stain to dry: Let the stain dry completely, following the manufacturer's instructions. Depending on the type of stain and the humidity and temperature of your workspace, this may take several hours or overnight.

Apply -

Posted: March 21, 2023Categories: Elkwall Wood Art Printing And DesignRead more »

Here are the differences between printing on wood using a UV flatbed printer vs. a roll printer for printing on canvas rolls:

Printing Technology: A UV flatbed printer uses a flatbed to hold the printing material in place while the printer head moves over it to deposit the ink. On the other hand, a roll printer feeds a roll of printing material through the printer while the printer head moves back and forth over it.

Material Compatibility: UV flatbed printers are suitable for printing on rigid materials, including wood, glass, acrylic, and metal. Whereas, roll printers are designed for printing on flexible materials such as canvas, vinyl, and fabric.

Print Size: UV flatbed printers can print on large, flat surfaces up to several feet in size. In contrast, roll printers can print on long rolls of material, which means they are best for printing larger images that can be printed across multiple panels.

Ink Drying: UV flatbed printers use UV-curable -

Posted: March 21, 2023Categories: Elkwall Wood Art Printing And DesignRead more »

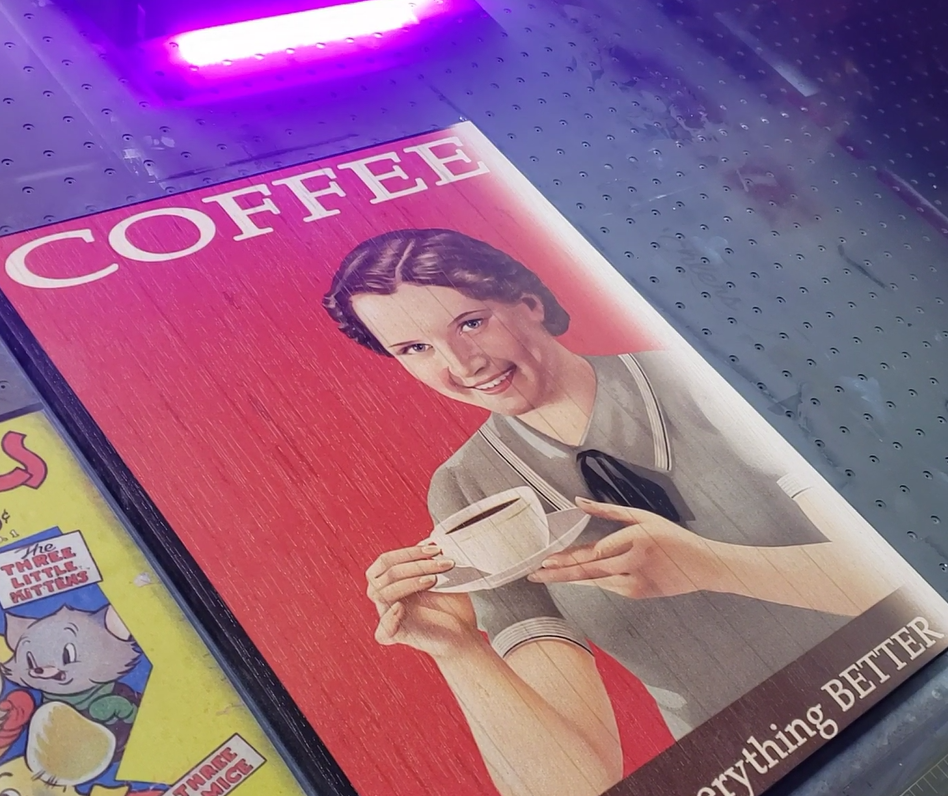

Our Wood Art Printing Process

The smell of fresh wood fills the air as we step into the wood printing studio. The studio is a cozy space, with natural light streaming in from the large windows. In the center of the room sits a state-of-the-art UV printer, surrounded by premium lumber waiting to be transformed into beautiful wood prints.

We start by taking a close look at the lumber that will be used for the wood prints. Each piece of wood is carefully selected, ensuring only the finest quality wood is used. The wood is then sanded to perfection, ensuring a smooth and even surface for printing.

Now it's time to see the UV printer in action. The wood is placed on the printer bed and the design is loaded into the computer. The printer uses UV technology to print the design directly onto the wood, creating a vibrant and long-lasting image.